Product Description

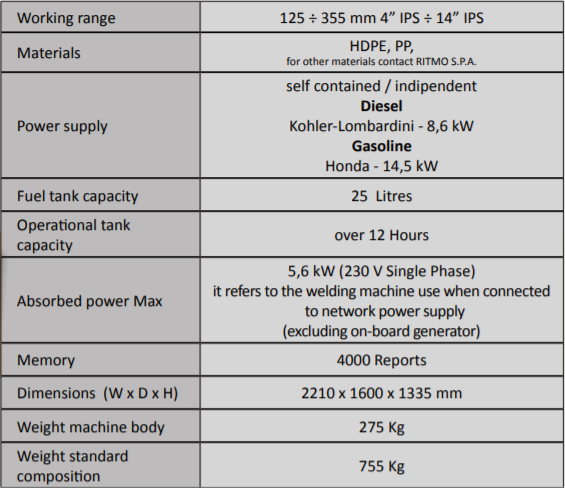

DELTA 355 ALL TERRAIN can be equipped with two types of engine: diesel low vibration and petrol. The engine, like an electrical generator, independently gives the necessary power supply to the machine during all its working and movement phases.

Machine composition:

- Removable control panel with data-logging, memory up to 4000 welding reports, GPS treacebility; USB port for welding report / data download / firmware upgrade

- Easy-life welding control system: hardware and software have been developed to interact to each other sharing data during the entire workflow. Once set the welding parameters up, the system guarantees the repetition of the welding cycle, avoiding errors. The operator only have to confirm the work phases on the just pushing a button. Possibility to pre-set 20 customized

- Chassis is equipped with front steering wheels and rear traction; parking brake, machine frame design for forklift lifting

- Removable machine body to work in tight spaces with shavings collection tray

- Dragging bar designed to weld between the 3rd and 4th clamp

- Ritmo patented insert quick release SMARTLOCK SYSTEM

- On-board electrical milling cutter with integrated locking handle system, safety switch-off device, motor thermic protection and gas spring to easily lift/lower the facer

- On-board heating plate with protection frame and insulated protection bag; gas-spring for easy lift/lower the heating plate

- Heating plate and facer locking system for safe transportation

- Two hydraulic rollers for pipe loading and unloading

- Kit for network power supply connection (upon request) excluding the machine engine and weld in closed enviroments

- 25 lt capacity tank for more than 12 working hours operating time

ON REQUEST (ACCESSORIES)

- Inserts Ø 4”÷ 12” IPS; 4”÷ 12” DIPS; Ø 125 ÷ 315 mm

- Tool for flange necks

- HS 355 rollers

- Print

- Kit for for IN-DITCH use

- Plug for network power supply connection

- Lifting kit